In the world of heavy machinery, precision, and efficiency are paramount. Komatsu, a leading manufacturer of construction and mining equipment, understands the need for comprehensive and detailed service information. One of the critical components of the Komatsu service manual is the inclusion of schematics and wiring diagrams. These visual aids are indispensable tools for technicians and engineers, ensuring that equipment maintenance and repair are carried out with accuracy and efficiency. This article delves into the various facets of these schematics and wiring diagrams, highlighting their importance and benefits.

Introduction to Komatsu Service Manual Contents

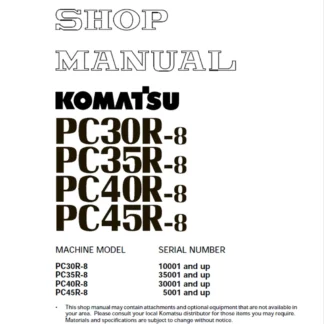

The Komatsu service manual is a treasure trove of information designed to assist technicians in maintaining and repairing Komatsu equipment. Each manual is meticulously compiled to include a wide range of content that caters to various aspects of machinery upkeep. From operational guidelines to detailed maintenance schedules, the manuals cover it all. A significant portion of these manuals is dedicated to schematics and wiring diagrams, which provide visual representations of the equipment’s electrical and hydraulic systems.

These service manuals are tailored to specific models and types of machinery, ensuring that the information is relevant and accurate. By offering a comprehensive overview of the machine’s inner workings, the manuals empower technicians to perform their tasks with confidence. Whether it’s a minor repair or a major overhaul, the detailed instructions and illustrations in the service manual are invaluable resources.

The inclusion of schematics and wiring diagrams is particularly noteworthy. These diagrams break down complex systems into understandable segments, making it easier for technicians to diagnose and address issues. The manuals are available in both digital and printed formats, providing flexibility and convenience for users. For more information, visit Komatsu Manual.

Importance of Schematics in Equipment Maintenance

Schematics are a crucial element in the maintenance of heavy machinery. They provide a visual representation of the electrical and hydraulic circuits within the equipment, illustrating how components are interconnected. This clarity is essential for technicians, as it allows them to understand the layout and function of various systems quickly.

Having access to detailed schematics can significantly reduce the time it takes to identify and resolve issues. Instead of relying on trial and error, technicians can refer to the schematics to pinpoint the exact location of faults. This precision not only saves time but also reduces the risk of further damage to the equipment.

Moreover, schematics are invaluable for preventive maintenance. By understanding the flow of electrical currents and hydraulic fluids, technicians can identify potential weak points and address them before they lead to significant failures. This proactive approach enhances the reliability and lifespan of the machinery.

The importance of schematics extends beyond the immediate repair process. They also serve as an educational tool, helping technicians to deepen their understanding of the equipment. This knowledge is transferable, enabling them to apply similar principles to other machinery. For comprehensive schematics, refer to the Komatsu Manual.

Detailed Wiring Diagrams for Troubleshooting

Wiring diagrams are another critical component of the Komatsu service manual. These diagrams provide a detailed map of the electrical system, showing how wires are connected to various components. This information is essential for troubleshooting electrical issues, which can be some of the most challenging problems to diagnose and repair.

With a wiring diagram, technicians can trace the path of electrical currents and identify where faults may occur. This level of detail is particularly useful for identifying issues such as short circuits, open circuits, and grounding problems. Without a wiring diagram, diagnosing these issues would be akin to searching for a needle in a haystack.

Wiring diagrams also play a crucial role in ensuring that repairs are conducted correctly. When replacing or repairing electrical components, it is vital to ensure that connections are made accurately. A wiring diagram provides a reference that technicians can use to verify their work, reducing the risk of errors.

Furthermore, wiring diagrams are essential for modifications and upgrades. When adding new features or components to the machinery, technicians can refer to the wiring diagram to understand how the new additions will integrate with the existing system. For precise wiring diagrams, visit Komatsu Manual.

Enhancing Repair Efficiency with Visual Aids

The inclusion of visual aids like schematics and wiring diagrams in the Komatsu service manual significantly enhances repair efficiency. Visual representations of complex systems make it easier for technicians to understand and interpret the information. This clarity translates into faster and more accurate repairs.

Visual aids reduce the cognitive load on technicians, allowing them to focus on the task at hand rather than deciphering complex text descriptions. This is particularly beneficial in high-pressure situations where time is of the essence. By providing a clear and concise visual reference, schematics and wiring diagrams streamline the repair process.

Moreover, visual aids facilitate better communication among team members. When multiple technicians are working on a project, having a common visual reference ensures that everyone is on the same page. This coordination is crucial for large-scale repairs and maintenance tasks.

The use of visual aids also contributes to better training and skill development. New technicians can quickly grasp the intricacies of equipment maintenance by studying schematics and wiring diagrams. This hands-on learning approach accelerates their proficiency and confidence. For visual aids that enhance repair efficiency, check out the Komatsu Manual.

In conclusion, the inclusion of schematics and wiring diagrams in the Komatsu service manual is a testament to Komatsu’s commitment to quality and efficiency. These visual aids are indispensable tools that enhance the accuracy and speed of equipment maintenance and repair. By providing clear and detailed representations of electrical and hydraulic systems, the service manuals empower technicians to perform their tasks with confidence and precision. For those seeking comprehensive and reliable service information, the Komatsu service manual is an invaluable resource. For more details, visit Komatsu Manual.