Service work on heavy machinery, such as changing cams and pushrods, is a detailed and intricate task that demands precision and thorough knowledge. When it comes to Komatsu equipment, using the factory Komatsu parts book manual is not only recommended but essential. This article delves into the importance of using the factory Komatsu parts book manual, provides a step-by-step guide to changing cams and pushrods, highlights the benefits of using genuine Komatsu parts, and discusses common mistakes that can occur when the parts book manual is not utilized.

Importance of Using the Factory Komatsu Parts Book Manual

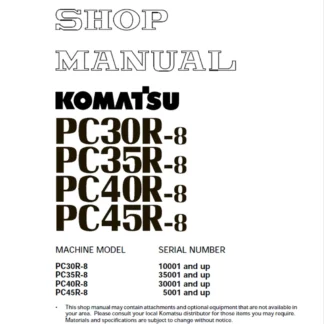

The factory Komatsu parts book manual is an indispensable resource for anyone undertaking service work on Komatsu machinery. It contains detailed diagrams and descriptions of every component, ensuring that technicians can identify the correct parts required for any job. This is particularly crucial when dealing with complex assemblies like cams and pushrods, where precision is paramount.

Using the manual helps in eliminating guesswork, which can lead to costly errors and prolonged downtime. The parts book provides exact specifications and part numbers, ensuring compatibility and optimal performance of the machinery post-service. Without this information, technicians might inadvertently use incorrect parts, leading to mechanical failures and potential safety hazards.

Furthermore, the manual aids in understanding the intricate relationships between different components. For example, the alignment and timing of cams and pushrods are critical for engine performance. The manual offers step-by-step instructions and visual aids that simplify these complex procedures, making them more manageable even for less experienced technicians.

The factory Komatsu parts book manual also serves as a comprehensive reference guide. It includes maintenance schedules, torque settings, and other essential details that are crucial for the longevity and reliability of the machinery. This ensures that all service work adheres to Komatsu’s high standards.

Additionally, having access to the official manual underscores a commitment to quality and professionalism. It reassures clients and stakeholders that the service work is being carried out with the utmost care and in adherence to the manufacturer’s guidelines.

For those looking to access the factory Komatsu parts book manual, it is available at komatsumanual.net. This website offers a wide range of manuals that are essential for anyone involved in the maintenance and service of Komatsu equipment.

Step-by-Step Guide to Changing Cams and Pushrods

Changing cams and pushrods in Komatsu machinery is a meticulous process that requires careful attention to detail. Here is a step-by-step guide to ensure the procedure is carried out correctly:

- Preparation: Before beginning, ensure that you have the factory Komatsu parts book manual from komatsumanual.net. Gather all necessary tools and genuine Komatsu parts. Disconnect the battery to avoid any electrical hazards.

- Accessing the Engine: Remove any components obstructing access to the engine, such as the valve covers. This might involve removing other parts, so refer to the manual for specific instructions.

- Removing Old Cams and Pushrods: Carefully remove the camshaft and pushrods. Be sure to follow the sequence recommended in the manual to avoid any damage to the engine block or other components. Keep track of the orientation and positioning of each part.

- Inspecting Components: Once the old parts are removed, inspect the camshaft bearings and pushrod seats for wear or damage. The manual provides detailed inspection criteria. Replace any worn or damaged components with genuine Komatsu parts.

- Installing New Cams and Pushrods: Lubricate the new cams and pushrods as per the manual’s instructions. Install them in the reverse order of removal. Ensure that the cams are correctly timed and the pushrods are properly seated. The manual provides precise torque settings and alignment procedures.

- Reassembling the Engine: Reattach any components that were removed to access the engine. Double-check all connections and ensure that everything is secure. Reconnect the battery and perform a final inspection to confirm that all parts are correctly installed.

Following these steps, as outlined in the factory Komatsu parts book manual, ensures that the cams and pushrods are changed correctly, maintaining the engine’s performance and reliability.

Benefits of Genuine Komatsu Parts in Service Work

Using genuine Komatsu parts in service work offers several significant benefits that contribute to the overall performance and longevity of the machinery. Firstly, genuine parts are designed and manufactured to meet Komatsu’s stringent quality standards. This ensures that they fit perfectly and function as intended, reducing the risk of mechanical failures.

The use of authentic Komatsu parts also enhances the reliability of the equipment. Genuine parts undergo rigorous testing and quality control processes, which means they are more durable and less likely to fail under demanding conditions. This is particularly important for components like cams and pushrods, which are critical for engine performance.

Another key benefit is the preservation of the manufacturer’s warranty. Using non-genuine parts can void the warranty, leaving the owner responsible for any subsequent repairs. By using genuine Komatsu parts, the warranty remains intact, providing peace of mind and financial protection.

Additionally, genuine parts are backed by Komatsu’s support and service network. This ensures that any issues can be promptly addressed, and technical assistance is available if needed. The parts come with detailed installation instructions and support from Komatsu’s technical team, which can be invaluable during complex service procedures.

The use of genuine parts also contributes to the overall efficiency of the machinery. Authentic parts are engineered to work seamlessly with other components, optimizing the performance and reducing wear and tear. This results in lower operating costs and longer intervals between maintenance.

Lastly, genuine Komatsu parts are readily available through authorized dealers and platforms like komatsumanual.net. This ensures that you can quickly obtain the necessary parts for any service work, minimizing downtime and keeping your machinery operational.

Common Mistakes When Not Using the Parts Book Manual

Neglecting to use the factory Komatsu parts book manual during service work can lead to several common mistakes that may compromise the machinery’s performance and safety. One of the most frequent errors is the incorrect identification of parts. Without the manual, technicians might use the wrong parts, which can lead to improper fitment and subsequent mechanical issues.

Another common mistake is the incorrect assembly of components. The manual provides detailed instructions on the correct sequence and torque settings for assembling parts like cams and pushrods. Failing to follow these guidelines can result in misalignment, insufficient lubrication, or even catastrophic engine failure.

Skipping the inspection of related components is another error that can occur when not using the manual. The parts book manual includes comprehensive inspection criteria for associated parts. Overlooking these checks can lead to undetected wear or damage, which may cause future breakdowns and costly repairs.

Improper lubrication is also a frequent issue. The manual specifies the type and amount of lubricant required for different components. Using the wrong lubricant or incorrect amounts can lead to increased friction, overheating, and premature wear of the parts.

Additionally, not using the manual can result in missed maintenance schedules. The parts book manual includes recommended maintenance intervals and procedures that are crucial for the longevity of the machinery. Ignoring these schedules can accelerate wear and lead to unexpected failures.

Lastly, safety protocols might be overlooked without the manual. The factory Komatsu parts book manual includes important safety warnings and guidelines to prevent accidents during service work. Ignoring these precautions can result in personal injury or damage to the equipment.

To avoid these common mistakes, it is essential to use the factory Komatsu parts book manual, which can be accessed at komatsumanual.net. This ensures that all service work is performed correctly, safely, and in accordance with Komatsu’s standards.

In conclusion, the factory Komatsu parts book manual is an essential tool for anyone involved in the maintenance and service of Komatsu machinery. It provides detailed and accurate information that is crucial for tasks such as changing cams and pushrods. By following the manual’s guidelines, technicians can ensure that the work is done correctly, using genuine Komatsu parts that enhance the reliability and performance of the equipment. Avoiding the common mistakes associated with not using the manual is also vital for maintaining the machinery’s integrity and safety. For access to the comprehensive factory Komatsu parts book manual, visit komatsumanual.net.