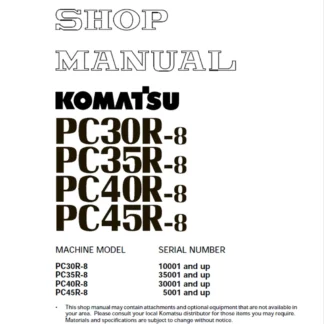

Komatsu machinery is renowned for its durability, reliability, and outstanding performance in various industries. However, like any complex equipment, it requires regular maintenance and occasional repairs to ensure it operates at its best. We specialize in repairing and servicing Komatsu machinery, providing expert solutions to keep your equipment running smoothly. Our team of skilled technicians is dedicated to delivering top-notch care for all models of Komatsu machinery. Visit Komatsu Manual for more information on our services.

## Expert Repairs for All Komatsu Machinery Models

Komatsu machinery comes in various models, each designed to meet specific operational needs. Whether you own a Komatsu excavator, bulldozer, wheel loader, or any other type of equipment, our repair services cover all models comprehensively. We understand the intricacies of each machine and are equipped with the necessary tools and expertise to diagnose and fix any issues that may arise.

Our repair process begins with a thorough inspection of your Komatsu machinery. We identify the root cause of the problem and provide you with a detailed report of the necessary repairs. This ensures transparency and helps you make informed decisions about your equipment.

We use only genuine Komatsu parts for all our repairs. This guarantees that your machinery will continue to perform at its best and maintains its value over time. Our commitment to quality and excellence sets us apart from other service providers.

In addition to repairs, we offer preventive maintenance services to help you avoid costly breakdowns and extend the lifespan of your equipment. Regular maintenance checks can identify potential issues before they become major problems, saving you time and money in the long run.

Our team is trained to handle the latest technological advancements in Komatsu machinery. We stay updated with the latest industry trends and continuously improve our skills to provide you with the best possible service. Trust us to keep your Komatsu equipment in top condition.

For more information on our repair services, visit Komatsu Manual.

## Comprehensive Servicing Solutions for Komatsu Equipment

Servicing Komatsu machinery is crucial for ensuring its longevity and optimal performance. Our comprehensive servicing solutions are designed to meet the specific needs of your equipment, regardless of its model or age. We offer a range of services, including routine maintenance, inspections, and performance enhancements.

Routine maintenance is essential for keeping your Komatsu machinery in peak condition. Our servicing solutions include oil changes, filter replacements, hydraulic system checks, and more. These routine tasks help prevent wear and tear, ensuring your equipment operates efficiently.

Inspections are a vital part of our servicing solutions. Our technicians conduct thorough inspections to identify any potential issues that may affect the performance of your Komatsu machinery. We use advanced diagnostic tools to detect problems early, allowing us to address them promptly and effectively.

Performance enhancements are another key aspect of our servicing solutions. We can upgrade your Komatsu machinery with the latest technology and components to improve its efficiency and productivity. Whether you need software updates or hardware upgrades, we have the expertise to enhance your equipment’s performance.

Our servicing solutions are tailored to meet your specific needs. We understand that every piece of machinery is unique, and we take the time to understand your requirements. This personalized approach ensures that you receive the best possible service for your Komatsu equipment.

For more details on our comprehensive servicing solutions, visit Komatsu Manual.

## Skilled Technicians for Reliable Komatsu Machinery Care

The quality of service you receive depends largely on the expertise of the technicians handling your machinery. Our team of skilled technicians is highly trained and experienced in working with Komatsu equipment. They possess in-depth knowledge of all Komatsu models and are committed to providing reliable care for your machinery.

Our technicians undergo rigorous training to stay updated with the latest advancements in Komatsu technology. This continuous learning process ensures that they are well-equipped to handle any issues that may arise with your equipment. Their expertise is backed by years of hands-on experience, making them the best in the industry.

We believe in a proactive approach to machinery care. Our technicians perform regular checks and maintenance to prevent potential problems from escalating. This proactive approach helps minimize downtime and ensures that your Komatsu machinery is always ready for operation.

Customer satisfaction is our top priority. Our technicians take the time to understand your specific needs and provide personalized solutions. They communicate clearly and transparently, keeping you informed throughout the repair and servicing process. This level of customer care sets us apart from other service providers.

In addition to their technical skills, our technicians are also trained in safety protocols. They adhere to strict safety standards to ensure that all repairs and servicing are conducted safely and efficiently. You can trust our team to handle your Komatsu machinery with the utmost care and professionalism.

For more information on our skilled technicians and their expertise, visit Komatsu Manual.

## Ensuring Optimal Performance of Your Komatsu Machines

Ensuring the optimal performance of your Komatsu machines is essential for maximizing productivity and minimizing downtime. Our specialized services are designed to keep your equipment running at its best, no matter the demands of your industry. We offer a range of solutions to enhance the performance of your Komatsu machinery.

One of the key aspects of maintaining optimal performance is regular servicing. Our comprehensive servicing solutions include everything from routine maintenance to performance enhancements. By addressing potential issues early, we help prevent costly breakdowns and ensure that your machinery operates efficiently.

We also offer performance tuning services to optimize the capabilities of your Komatsu equipment. Whether it’s adjusting the hydraulic systems, fine-tuning the engine, or upgrading software, our technicians have the expertise to enhance your machinery’s performance. These enhancements can lead to increased productivity and reduced operational costs.

Our preventive maintenance programs are designed to keep your Komatsu machinery in top condition. Regular maintenance checks help identify potential problems before they become major issues, ensuring that your equipment remains reliable and efficient. These programs are tailored to meet the specific needs of your machinery, providing you with peace of mind.

We use advanced diagnostic tools to monitor the performance of your Komatsu equipment. These tools allow us to detect any deviations from optimal performance and address them promptly. By continuously monitoring your machinery, we can ensure that it operates at its best, even in the most demanding conditions.

For more information on how we can help ensure the optimal performance of your Komatsu machines, visit [Komatsu Manual](https://komatsumanual.net).

Maintaining and repairing Komatsu machinery requires specialized knowledge and expertise. Our team is dedicated to providing the highest quality of service to ensure that your equipment operates at its best. From expert repairs to comprehensive servicing solutions, we have the skills and experience to meet all your Komatsu machinery needs. Trust us to keep your equipment in top condition and maximize its performance. For more information on our services, visit Komatsu Manual.